Ordinarily, the micropile shaft is possibly driven or drilled into posture. Some kind of bearing element must be created if the desired pile capacity can not be attained in stop bearing and side friction together the pipe. This could entail drilling a rock socket, filling it with grout, and putting in a complete duration, higher-toughness threaded bar In the event the tip is roofed in rock.

b) Micropiles are employed for rehabilitation jobs along with new constructions in hard and entry constraint terrains and settlement prone places. For rehabilitation functions in congested and low headroom top basements, micropiles confirm for being a preferred possibility.

Following accomplishing the First tremie grouting, force grouting is finished concomitantly Using the lifting of your casing from the bond zone through a pre-mounted tube.

Load testing is critical to validate micropile general performance. Down below is an illustration of typical load check details for micropiles:

The key benefit of a micropile is its capability to determine in terribly engorged and minimal top parts and on any soil surface area despite its type.

Micropiles are typically employed when there are actually tricky ground disorders, like pure or man-built obstructions, sensitive floor with adjacent structures, constrained obtain/low headroom and/or karstic geology.

Micropile installation consists of drilling a little-diameter gap, placing a metal casing or reinforcement bar in the hole, and afterwards filling it by using a cement grout mixture.

The piles verticality and duration must also be monitored and documented. A check pile is made in the beginning in the function and cargo analyzed to two hundred% of the design load in accordance Along with the typical specification ASTM D 1143.

Reinforcing metal, usually an all-thread bar is inserted in the casing. Large-strength cement grout is then pumped in the casing. The casing could prolong to the complete depth or close earlier mentioned the bond zone, With all the reinforcing bar extending to the full depth.

The grouting to the group A micropiles is set beneath gravity. In group B, grout is injected under pressure into the opening, nevertheless the stress is constrained to stop hydrofracturing on the nearby soil. Team C micropiles are put in in two ways: to start with, a primary grout is tension-placed on hydrofracture the surrounding floor, and then, just ahead of the main grout sets, a secondary grout is injected via a manchette tube.

c) Put reinforcement with centraliser from the borehole and followed by tremie grout with cement water combine. d) The tremie grouting will be followed by a tension grouting by means of preinstalled grouting tubes with at the same time lifting from the casing.

Micropiles are บริการรับตอกเสาเข็มไมโครไพล์ deep foundation utilized when very restricted space or headroom is accessible for execution with standard pile rigs. These piles are also known as as minipiles, pin piles, needle piles and root piles.

The piles ought to be put in in such a sequence the load carrying capacity of Earlier set up pile is not minimized. The sequence of piling shall be as per Operating drawings.

The most crucial benefit of a micropile is its power to determine in terribly engorged and small peak regions and on any soil surface regardless of its form.

Rick Moranis Then & Now!

Rick Moranis Then & Now! Bug Hall Then & Now!

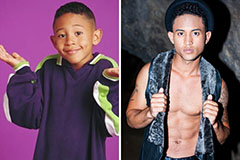

Bug Hall Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!